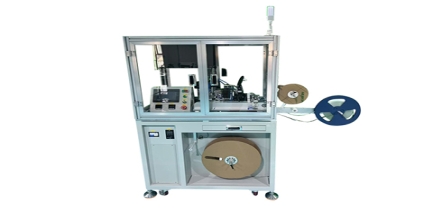

Comprehensive Automated Taping Solutions

Our automated taping solutions provide a complete, turnkey system for precision component packaging. Designed for maximum efficiency and reliability, these integrated systems seamlessly handle everything from miniature chips to large connectors. By combining advanced vision inspection, high-speed robotics, and intelligent software, we deliver a future-proof solution that eliminates manual errors, maximizes SMT line throughput, and ensures flawless feeding for a wide range of industries—from consumer electronics and automotive to medical devices and industrial controls.

1. Consumer Electronics & High-Speed EMS

Challenge: Extreme production speeds, massive component volumes (e.g., resistors, capacitors, ICs), and zero tolerance for feeding errors that cause SMT line downtime.

Our Solution: High-speed automatic taping machines equipped with multi-lane feeding systems and high-speed pick-and-place heads, capable of processing tens of thousands of components per hour. Integrated vision systems ensure correct component orientation and polarity, seamlessly connecting with upstream testing processes to provide uninterrupted component supply for smartphones, laptops, and wearables.

2. Automotive Electronics & High-Reliability Applications

Challenge: Stringent zero-defect requirements, full traceability (IATF 16949), and the need for components to withstand harsh environments like high temperatures. Packaging processes must be ESD-safe and contamination-free.

Our Solution: High-reliability automated taping solutions. Compatible with high-temperature carrier tapes and integrated with online laser marking for batch/QR code traceability. Our ESD-safe and cleanroom-compliant systems ensure the packaging integrity of critical components like ECUs, sensors, and power modules.

3. Industrial Control & Power Devices

Challenge: Diverse, often irregularly shaped components (e.g., large connectors, relays), medium-volume batches, and the need for highly flexible and compatible systems.

Our Solution: Versatile, flexible automated taping systems. Featuring a modular design for quick changeover of fixtures and tape lanes, easily handling components from 8mm to 104mm wide. We provide custom carrier tape cavity designs to automate taping for traditionally hand-placed components, significantly boosting assembly efficiency for industrial control boards.

4. Medical Electronics & Semiconductors

Challenge: High-value components, extreme requirements for cleanliness and prevention of material mix-ups. Any contamination or orientation error can lead to failure in expensive medical devices (e.g., pacemakers, diagnostic equipment).

Our Solution: Cleanroom-grade, high-precision taping systems. Equipped with high-resolution vision inspection to verify component markings and authenticity, automatically rejecting defects. The system meets high cleanliness standards and can be optioned with in-line weighing, RF testing, and other functions for integrated "test-sort-tape" processing, ensuring the quality of medical and semiconductor components.

5. LED & Optoelectronics Industry

Challenge: LEDs require sorting by brightness, color temperature, and voltage (binning) before packaging. Manual operations are inefficient and prone to error.

Our Solution: Dedicated LED binning and taping all-in-one machines. These integrate optical measurement instruments with automatic taping machines to automatically perform feeding, photoelectric testing, sorting, and taping on a single line, dramatically improving the automation and accuracy of LED production.