Case Studies

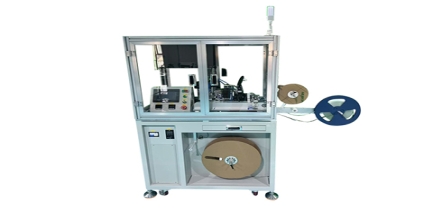

XYZ Automatic Taping Machine to Improve SMT Tape-and-Reel Packaging Efficiency

XYZ introduces its next-generation automatic taping machine featuring high-speed feeding, precision pocket alignment, CCD vision inspection, and flexible automation options—designed for modern SMT and SMD packaging applications.

Connector & Terminal Manufacturers

A connector manufacturer needed custom pocket size and reinforced carrier tape structure for delicate terminals.

EMS / PCBA Production Support

A mid-size EMS company required fast, flexible taping to support its SMT lines during peak orders.

Automotive Electronics Components

An automotive parts supplier needed reliable carrier tapes with strong mechanical stability to prevent deformation during shipping.

LED Packaging & Sorting Line

An LED packaging factory needed high-efficiency taping for LED chips with accurate positioning and minimal damage.

Passive Components Packaging

A leading passive component supplier needed to improve packaging speed and reduce manual errors during MLCC and resistor taping.