INTRODUCTION

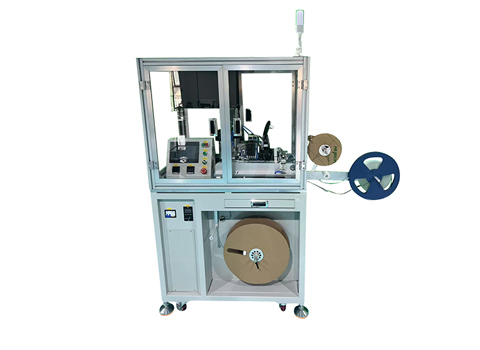

The PPU Automatic Taping Machine AU-200 is a high-efficiency tape-and-reel packaging system engineered for SMD electronic components. Equipped with a precision feeding mechanism and advanced sealing control, the AU-200 ensures accurate pocket alignment, stable part loading, and consistent sealing quality for every reel.

Designed to meet the requirements of modern SMT and SMD production lines, the AU-200 supports EIA-standard carrier tapes and is compatible with a wide range of component shapes and sizes. The system offers smooth operation, fast setup, and excellent repeatability—making it suitable for high-volume manufacturing as well as flexible batch processing.

With strong mechanical reliability and an intuitive operation interface, the AU-200 reduces manual handling errors, improves taping accuracy, and increases overall production output. Optional feeding systems, including vibration bowls, tray loaders, or customized feeders, allow manufacturers to match the machine to their specific components.